Dowell3d is a manufacturer with 10 years of experience in R&D, production, and export of large-scale industrial 3D printers.

It has hundreds of easy-to-use large-format 3D printers designed for industrial applications. They are suitable for producing high-quality parts in any environment, whether it is industrial parts, molds, furniture, portrait prototypes, statues, car parts, boats, or end-use parts, The Dowell 3d printer is a durable and cost-effective machine.

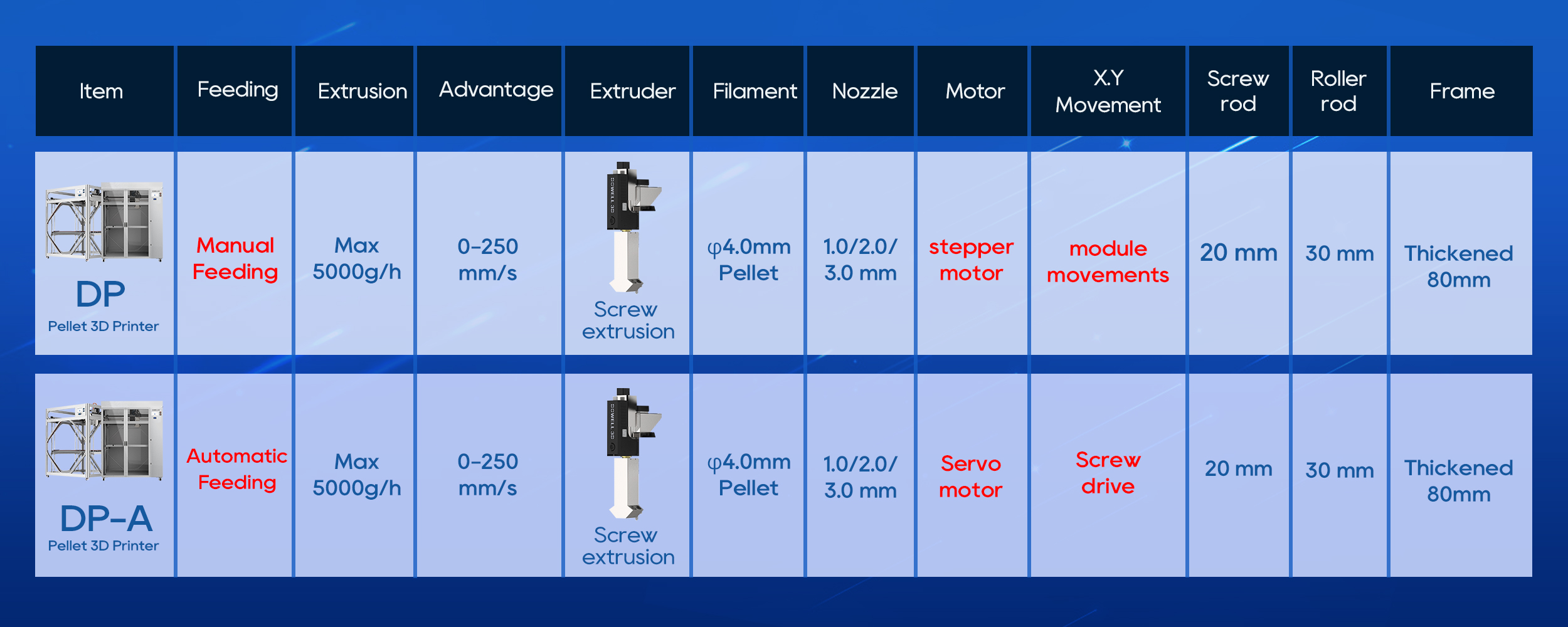

DOWELL 3D Printer Series Configuration Comparison

Why Choose Dowell 3D Pellet Printer?

-We are one of the largest 3D printer manufacturers in the global market.

-Provide various customized and personalized 3D printers.

-Provide high quality and free after-service guarantee.

-Fast and convenient logistics services.

Specification

|

Printer model |

DP Series 3D Printer |

|

Printing size |

900*900*1000mm to 1500*2300*1600mm |

|

Platform |

0-100°c 6mm tempered glass |

|

Frame structure |

80mm thickened aluminum section |

|

Extruder |

Screw extrusion |

|

Nozzle diameter |

1.0/2.0/3.0mm |

|

Extrusion flow rate |

4000-5000g/hour |

|

Cooling system |

Water cooling |

|

Nozzle temperature |

0-420°c |

|

Material |

4mm pellet recommended |

|

Operation interface |

7" full-color touch screen |

|

Operation firmware |

Based on Klipper |

|

File format |

stl/ obj/ gcode |

|

Input power |

110V/220V |

|

Basic functions |

*Auto-leveling *Filament sensor *Remote control *Wifi connection *Visible Printing status |

|

Customization options |

*60°c enclosure *Printing size *Auto feeding system |

DP Pellet 3D Printer Advantage

1: Cheap Material cost

Pellets are easy and economical to manufacture in huge volumes and consequently have a low retail price. Filament is more expensive because it takes longer to produce (it is usually extruded from pellets) and provides a high level of convenience for FDM users.

2: Wide range of materials

A wide variety of plastics is available in pellet form, and some materials are easier to make into pellets than filaments due to their chemical composition.

3:Large-format printing

Pellets can be fed into a hopper continuously without interrupting the print, which is useful for printing large objects. Conversely, if a large-format print requires more than one spool of filament, the filament must be switched mid-print, which can lead to imperfections.

4:Fast printing speed

Pellet extrusion and its barrel and screw system enable fast flow and deposition rates. The nozzle can also have a wider diameter, allowing more material to be squeezed out in less time. The maximum throughput of dowell Pellet printer can reach 5000g/hour.

5: Wide application range

Material diversity and high-speed printing provide users with a wider range of material choices to meet different application requirements. Dowell pellet 3d printer is widely used in industrial manufacturing fields such as prototyping, custom parts production, tool and fixture manufacturing, etc.

6: Environmentally friendly and sustainable

In addition to using virgin particle raw materials, Dowell pellet 3d printing machine FGF technology can also use recycled materials for printing, thereby significantly reducing or even eliminating plastic waste, which is beneficial to environmental protection. Failed prints or support structures can be crushed and reused for printing.

Screw Extrusion & 3-stage temperature control

Dowell 3d pellet printer extruder has 3 heating zones to melt the plastic into a uniform melt and maintain a constant temperature and flow rate for consistent extrusion.

Real Auto Leveling

High-precision 3D TOUCH auto leveling, 64-Point matrix detection, ensures more accurate results.

Water Cooling & Heat Dissipation

Strong force 3-stage screw extrusion

High Extrusion Speed

Pellet extrusion and its barrel and screw system enable fast flow and deposition rates. The nozzle can also have a wider diameter, allowing more material to be squeezed out in less time. The maximum throughput of dowell Pellet printer max can reach 5000g/hour.

High-temp heating bed

Platform composition: iron plate + silicone sheet + 6mm tempered glass, which heats evenly and quickly, the thickened tempered glass does not deform and has perfect flatness, strong bearing capacity, and an easy removal model.

Noiseless Drive

It has both the advantages of silence and high efficiency, controlling the working noise at about 60dB while ensuring the high efficiency of the drive. Whether at home or in the workshop, you don’t have to worry about noise.

Remote Management

Dowell 3d printer is equipped with remote maintenance modules to analyze possible anomalies and to reduce the possibility of downtime for the advantage of productivity. The remote management feature includes sending software updates to allow the DOWELL 3D Printer to evolve over time, acquiring new features, parameters, and intelligence.

Auto resume printing from power recovery

In case of an unexpected power outage, the printer automatically memorizes the current position, stores the printing data, lowers the workbench, and retracts the consumables. When power is restored, the printer will continue printing from the point where the power was cut off.

Standard printer model sizes

The standard printer we offer 14 models, you can also contact us to customize your printer.

Customization Options

The default machine is an open-frame model with manual feeding.

You can contact us to customize a constant temperature housing and automatic loading system for you.

Company Profile

Luoyang Dowell Electronics Technology Co., Ltd is a technology-based enterprise integrating R&D, manufacturing, and sales based on technological innovation and core patents.

Dowell technology has independent patented technologies, relying on a strong technical research and development, production management, quality control, and market development team, it has won the recognition of users in the global market with high-quality after-sales service, and has become the leading enterprise of Large 3d printers.

Yes, we are a direct manufacturer focused on developing and producing large industrial 3d printers.

T/T (Bank transfer), Paypal, West Union, Credit card, WeChat Pay, Ali Pay, T/T

DHL, UPS, FedEx, TNT, sea shipping, air freight, by train.

5-How do you guarantee the quality of the printer?

DP9-16 (900*900*1600mm)

4mm granule material

80mm Super strong frame

4000~5000g/hour fast extrusion

0-200mm/s high printing speed

1500*2300*1600mm huge building size

Manual feeding system

Contact us to help you find the most cost-effective 3D printer for your application!